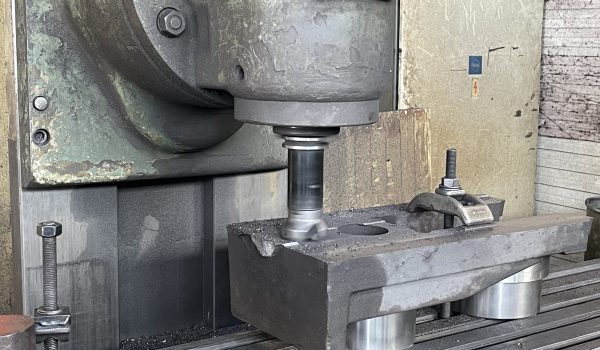

CNC Milling Machine

CNC, which stands for Computer Numerical Control, has revolutionized the future of the molding industry and has brought ease in the molding process. I am not exaggerating if I say that CNC milling is one of the most impressive technological advances of this century. This machine has a small computer. or a microcomputer that plans the process of using these machines to perform precise movements and tasks and provides the possibility of taking a digital design of an object and producing it in physical form from raw materials

CNC makes it possible to achieve unparalleled precision and convert a specific numerical code into Cartesian coordinates, ensuring that each manufactured part is produced with absolute precision, down to the smallest detail, which is virtually impossible to do by hand.

In fact, the CNC milling machine is like a robot and after programming, it executes all the instructions according to the system. The programs in this device are coded by the programmer and stored in the computer memory. Almost most of the existing materials can be machined through CNC milling, but the choice of the main material is completely related to the type of product required. The materials used in most parts include aluminum, copper, brass, wood and plastic.

A milling machine is one of the cutting machines that operates using computer software and is used in various businesses. In fact, this device has a very high precision in the process of cutting objects, and with its rays, it can cut an object in the best possible way.

For this reason, there are wide applications of this device. Maybe some people limit the use of cnc milling machine only to the industry, while we see the use of these milling machines in all fields, especially medical fields and commercial fields. Making artificial molds, cutting car parts, cutting different objects and applications in aerospace are all among those cases where cnc is used.

Making prosthetic molds

One of the main uses of the CNC milling machine is that it can make artificial and prosthetic molds from a simple frame so that these molds can be presented to customers with the utmost elegance and accuracy. In fact, the main purpose of using these devices is to achieve this elegance. In medical sciences, when they want to create an initial mold to test and fix weak points, they use these devices, and if the mold is approved, they make it in mass production and present it to the market.

Making car parts

Another application of cnc milling machine that works using computer programs is the manufacture of car parts. If you also pay attention to the different parts of the cars, you will understand that these parts are produced with complete elegance and have many complications in their surface or internal structure, which can only be created by using advanced devices such as cnc machines. .

Note that in the construction of car bodies using metals, these devices are also used, because with the laser technologies of cnc devices, you can have the best productivity in the shortest time and finally produce all car structures with excellent quality.

Application in aerospace

It may be surprising for you that we say that cnc milling machine is also used in aerospace, but you should know that in the aerospace industry, some titanium parts or hard parts cannot be cut easily with available tools because these parts are very strong. Therefore, cnc cutters are used to cut such parts to increase the accuracy of the work and minimize the speed of these processes.

Application in cutting

Another main and important use of these devices is to perform cutting services. The meaning of cutting services is the services in which all kinds of metal parts such as doors and windows are cut and then used. Nowadays, they use these devices to create beautiful designs on metal doors and windows. Therefore, we cannot consider any limitation in application for such systems.